Precautions for dismantling aluminum shuttering system

The dismantling of the aluminium shuttering system is a crucial phase in the construction process, which requires strict adherence to a series of precautions. Firstly, it is essential to conduct a comprehensive safety assessment and develop a detailed dismantling plan before commencing the dismantling process. Secondly, the operators must possess relevant skills and knowledge regarding the aluminium shuttering components and dismantling methods. During the dismantling process, special attention should be given to the handling of support bars to prevent loosening and collisions that may result in unsafe conditions. Additionally, it is important to select appropriate tools and equipment and proceed with the dismantling in an orderly manner according to the specified sequence. After completing the dismantling process, it is crucial to promptly clean up the work area and ensure a tidy and organized site. Furthermore, regular inspections should be conducted to assess the safety conditions during the construction process, and training and education should be provided to construction personnel to enhance their safety awareness and skill levels. By strictly adhering to the precautions, the safe dismantling of the aluminium shuttering system can be ensured, thereby facilitating the smooth progress of the construction process.

● Preparation for aluminium shuttering dismantling

1. Erecting a work platform: Prior to dismantling, ensure the construction site has a stable and secure work platform. The work platform provides a safe and stable operating environment, facilitating the removal and cleaning of aluminium shuttering by workers.

2. Inspecting concrete strength: Prior to commencing the aluminium shuttering dismantling operations, it is imperative to verify that the concrete has achieved the design allowable strength. Only when the concrete attains sufficient strength can the dismantling work proceed, in order to avoid compromising the stability of the structure.

3. Essential tools: For ensuring construction safety during the dismantling process, construction personnel should wear safety helmets, gloves, and other protective equipment to prevent accidents. Additionally, since aluminium shuttering material is made of aluminium alloy, specific professional tools such as formwork removal tools, hammers, wrenches, power drills, and hand saws are required for dismantling. The selection of appropriate tools should be based on the specific circumstances.

4.Inspect the formwork: Before dismantling, it is necessary to inspect the formwork for any damage or deformation. If any issues are identified, repairs or replacements should be carried out.

5.Dismantling sequence: Follow the predetermined dismantling sequence outlined in the plan to ensure a systematic dismantling process. Aluminium formwork shuttering removal sequence: Non-load-bearing sections → Load-bearing sections.

Non-load-bearing sections: Preparation→ Dismantle staircase treads → Remove side shuttering aluminium beam → Remove adjustable push pull props → Remove steel walers → Dismantle wall column formworks.

Load-bearing sections: Preparation → Dismantle bottom formwork of beams → Remove floor transition formworks → Remove slabs formwork → Dismantle bay windows → Remove kickers.

● Dismantling techniques for aluminium shuttering plates:

For vertically positioned aluminium shuttering plates, it is advisable to start the dismantling process from the top and proceed downwards. This step-by-step approach prevents damage caused by the gravitational force between formwork panels. It effectively controls the progress of dismantling, ensuring safety and ease of operation.

For aluminium shuttering plates with larger spans, it is recommended to begin dismantling from the center and then work towards both ends separately. This method minimizes the impact of lateral forces and instability

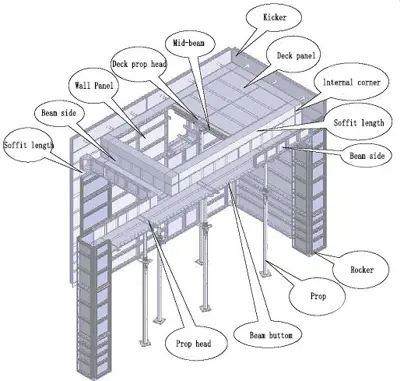

● Dismantling of aluminium shuttering system

1、When removing the formwork of wall, it is generally recommended to start the dismantling process about 12 hours after pouring the concrete. The dismantling work should begin with the removal of diagonal braces, followed by the removal of steel waler, waller clamp, flat tie, and then the removal of the connecting pins between the aluminium shuttering pans.

When removing aluminium shuttering pans, a pry bar can be used to gently pry the formwork away from the wall to ensure that the wall structure is not damaged during the dismantling process. At the same time, the formwork and accessories should be promptly removed after dismantling, and the formwork located in the same position should be laid flat and stacked for easy access and use the next time.

2、The dismantling work should start from the shuttering aluminium beam, followed by dismantlin the pins and wedges between the adjacent deck panel and the beam and then removing the bottom slab of the beam. Next, the deck panel can be removed by dismantling the connecting pins between the deck panel and the adjacent beam, and separating the adjacent formwork using a panel puller. It is strictly prohibited to loosen or dismantle the support of the deck panel and the beam.

Special attention should be paid when dismantling the deck formwork: when removing each piece of the aluminium shuttering componentsit is necessary to have a person hold the formwork first. After dismantling the connecting pins and wedges, directly dropping the formwork onto the floor is strictly prohibited.

3. Removal of shuttering aluminium beam: The shuttering aluminium beam can be dismantled when the concrete reaches approximately 70% of its design strength. Typically, the removal of the bottom formwork can commence around 36 hours after concrete placement, followed by the gradual dismantling of the side formwork. During the dismantling process, it is essential to ensure the stability of the shoring props, ensuring they remain in their original state without becoming loose. This can be achieved by inspecting the fastening state of the shoring props and making adjustments using appropriate tools. Additionally, strict adherence to the construction schedule and relevant safety regulations is crucial, ensuring that personnel wear personal protective equipment and take appropriate safety precautions to prevent any accidental injuries. By optimizing and following these steps, the shuttering aluminium beam can be dismantled efficiently and safely, ensuring smooth progress of the construction project.

3.To ensure that the concrete strength meets the specified requirements, the dismantling time of the shoring props should be determined based on different supporting parts of the aluminium shuttering. In general, the bottom shoring props of the beam and deck can be removed after 15 days, while the cantilever beam shoring props can only be removed after 28 days. When removing each shoring props, one hand should hold the shoring props while the other hand should hammer in the direction of the adjustable support point to loosen and remove the support rod. This operation can not only effectively prevent accidents but also ensure the long-term use of the aluminium shuttering pans.

During the construction of aluminium shuttering sheet, if a bent or deformed panel occurs, it should be promptly transported to the processing plant for correction to ensure the quality and service life of the panel. At the same time, dismantled accessories should be cleaned, counted, and transferred to the upper level so that they can be quickly used next time. In order to facilitate dismantling and transportation, special ladder holes or transporter boxes should be reserved in advance to transport the formworks through these channels to the upper level, while scattered accessories can be transported to the destination via stairs. This can improve construction efficiency and also avoid personnel and equipment safety accidents caused by improper operation.

● Requirements of aluminium shuttering technology

1.Prior to dismantling, it is necessary to obtain the guidance of aluminium shuttering technology.

2.Before commencing the dismantling process, a working platform should be erected to ensure safety, with a minimum of two individuals working in collaboration.

3.The dismantling of aluminium shuttering pans must occur once the concrete strength has reached the designated level. During the dismantling process, it is essential to remove the formworks one by one and avoid removing all the pins and wedges at once.

4. It is crucial to avoid loosening or colliding with the shoring props while dismantling aluminium shuttering pans. If any phenomena such as concrete sticking to the formwork are identified during the dismantling process, the dismantlement should be temporarily halted.

5. The dismantled aluminium shuttering should be immediately cleaned of surface dirt using a scraper, followed by the timely application of aluminium shuttering oil.

6.Aluminium shuttering pans that have undergone bending or deformation during the construction process should be promptly transported to the processing workshop for rectification.

7.Disassembled components should be cleaned using specialized aluminium shuttering cleaning chemical.

8. The disassembled aluminium shuttering components are conveyed to the upper levels through pre-determined passage holes, while scattered accessories are transported using stairs.

● Recommended