Aluminium formwork

Aluminium formwork price: 130USD/m2

● What is aluminium formwork?

Aluminium formwork is a type of construction concrete formwork system made from aluminium alloy materials, it is composed of a series of aluminium formwork panels and connectors, which are used for temporary support and positioning in concrete construction projects.

The aluminium formwork construction has the characteristics of fast construction, good construction quality and low construction cost. The aluminium concrete formwork is a revolutionary building formwork that offers a combination of lightweight and high strength. It has gained significant attention and wide application from real estate developers of high-rise buildings and villa community. It represents a technology sophisticated in concrete engineering formwork.

● Aluminium formwork specification

| Item: | Aluminium formwork for concrete |

| Aluminium formwork material: | 6061-T6/6082-T6 aluminium alloy |

| Thickness of Material: | 4mm |

| Type: | Flat formwork, corner formwork, beam formwork, etc. |

| Formwork Weight: | 18-22kg |

| Aluminium formwork thickness: | 65mm |

| Safe Working Load: | 60kN/m2 |

| Cycle Times: | ≥200 |

| Shape: | Rectangular, customized |

| Size: | 0.5m-11.85m, non-standard: custom-made as your requirement |

| Process: | Drilling, bending, welding, precise cutting, punching, etc. |

| Package: | Standard pallet with waterproof film, or according to your requirement. |

| aluminium formwork cost | 130USD/m2 |

● Aluminium formwork components

Aluminium formwork material is aluminium alloy profiles, which are processed and welded using mechanical techniques. Aluminium formwork components consists of a formwork system, support system, fastening system, and accessory system.

1. Aluminium formwork panels system: The aluminium formwork panels provide the enclosed surfaces necessary for constructing concrete structures, ensuring that the building structure takes shape during concrete pouring.

2. Supporting system: It plays a supporting role in the construction using aluminium composite formwork, ensuring the stability of the floor, beam bottom, and cantilever structure. (Mainly including steel pipe support, diagonal brace, etc.).

3. Fastening system: It ensures that the width of the formwork aluminium remains unchanged during concrete pouring, preventing deformation and eliminating the risk of swelling or bursting of the formwork. (Mainly including flat ties, waller clamp).

4. Aluminium formwork parts system: The aluminium formwork parts system consists of connecting components. It mainly includes aluminium formwork wedge pins, and wedges, etc. These parts connect individual aluminium formwork panels into a monolithic aluminium formwork.

● Aluminium formwork advantages

With the development of urban modernization, there are increasing numbers of high-rise buildings, and people's demands for green construction and engineering quality have also increased. Traditional wood formwork construction techniques can no longer meet current construction requirements in terms of safety, efficiency, and engineering quality. Aluminium formwork panels are a new generation of building formwork that has gradually occupied the construction market due to their environmental protection and high reuse rate. Our Aluminium Formwork has been exported to India, US, Malaysia, Singapore, etc.

Aluminium formwork construction technology is suitable for the construction of concrete structural walls, horizontal floor slabs, columns, beams, climbing forms, and pipe corridors. It has significant characteristics in construction methods. Compared with traditional wood and steel formwork construction techniques, advantages of aluminium formwork is obvious in project duration, quality, safety, environment protection, and economic benefits.

1. aluminium formwork can shorten the construction period

The china aluminium formwork features high strength and lightweight (the weight of aluminium formwork is only 21-25 kilograms per square meter).

The aluminium formwork installation and disassembly is very easy.

They are easy to assemble and Disassembly , with all materials passed vertically by workers without the need for cranes or unloading platforms. The construction process is highly efficient, with a standard floor completed in just five days. The support system, composed of vertical support rods and rigid connections with the aluminium formwork, forms a portal frame structure between each of the support rods. Even after the concrete strength requirements are met, the support system remains in place.

2. Our aluminium formwork for sale gives good pouring effect

With the usage of aluminium formwork for concrete, the overall visual effect of the poured concrete is excellent, with a pass rate of almost 100% in terms of visual quality, flatness, verticality, and cross-sectional dimensions. Due to the excellent strength, stiffness, and stability performance of the aluminium formwork system and advanced aluminium formwork design, the wall flatness of structures constructed using aluminium formwork systems can reach a horizontal range of (-3, 3).

3. Our aluminium formwork for sale provides safe and reliable construction

The aluminium formwork panels have a high load-bearing capacity, reaching 30KN-40KN per square meter (the maximum test load can reach 60KN). When using this aluminium formwork for construction, the amount of construction waste on site is minimal, and the support system is simple and stable. The accessories aluminium formwork can be reused, and after completing the construction, there is no garbage left on site, and the support system is easy to dismantle. Therefore, the use of this china aluminium formwork panel is environmentally friendly, clean, and hygienic.

▲ What are the types of aluminium formwork?

◆ There are different types of aluminium formwork, according to the connection methods of aluminium system formwork, aluminium formwork manufacturers divided aluminium formworks into aluminium formwork flat tie and aluminium formwork tie rod.

1. Aluminium formwork flat tie

The aluminium formwork flat tie involves passing the flat tie through the connection hole and connecting the inner and outer aluminium wall formwork using pins and wedges. The kinds of aluminium formwork systems are mainly used abroad and are not suitable for wall and column widths exceeding 200 mm.

2. Aluminium formwork tie rod

The aluminium formwork tie rod is connected by wall tie for aluminium formwork, connected holes with a diameter of about 20mm, and the distance between each connection hole does not exceed 800mm. In addition, the back rib system is connected to the outside of the aluminium formwork to improve its bearing capacity. The kinds of aluminium formwork system are mainly used for high-rise and super high-rise buildings.

▲ Classification by degree of commonality, aluminium formwork manufacturers divided aluminium formworks into:

1. Standard aluminium formwork panels: commonly used aluminum formwork that meets specific sizes and specifications;

2. Non-standard aluminium formwork: aluminum formwork that is customized according to specific project requirements and has non-universal shapes and specifications.

▲ Classification by application, aluminium formwork manufacturers divided aluminium formworks into:

1, aluminium wall formwork: It is uitable for wall construction of building.

This kind of aluminium formwork thickness is generally below 3mm, aluminium formwork weight is light and it is easy to install.

2, aluminium formwork beams: It is suitable for the beams and slabs construction of building. This kind of aluminium formwork thickness is generally above 3mm, It can provide a better support and stability.

aluminium formwork beams can improve construction efficiency while ensuring the flatness and uniformity of the building.

3, Column aluminum formwork: Specially used for the column construction of building.

4, Aluminium formwork staircase: Specially used for the column construction of building.

The aluminum formwork for stairs has high strength and good stability. The concrete surface is highly flat after demoulding, which can eliminate the need for subsequent surface treatment steps and save costs.

● Aluminium formwork vs conventional formwork

The differences between aluminum formwork and conventional formwork are as follows:

1, Materials and features

The aluminum formwork system is made of aluminum alloy profiles, and has the characteristics of light weight, high strength, overall stability, quick assembly and disassembly, and multiple reuse.

;Conventional wooden formwork is made of wood, with low cost, but weak strength, non-waterproof, easy to mold and rot, and low reuse rate. Conventional steel formwork has the characteristics of high strength and good concrete appearance after demolding, but the texture is too heavy, so the construction with conventional steel formwork requires mechanical equipment assistance, and it is easy to rust.

2, Construction efficiency and cost

The aluminum formwork system is a quick-disassembly formwork system. A set of formwork can be used to construct one floor in four to five days. It is easy to assemble and can be carried and assembled manually. It is easy to construct and efficient. The multiple reuse of aluminum formwork also greatly reduces the construction cost.

Conventional formwork is not as good as aluminum formwork in terms of construction efficiency and cost. For example, the reuse rate of wooden formwork is low and it consumes a lot of wood resources; steel formwork requires mechanical equipment to assist in construction due to its heavy material, which increases the construction cost.

3, Environmental protection and energy saving

All materials of the aluminum formwork system are renewable, which comply with the national regulations on energy conservation, environmental protection, low-carbon emission reduction for construction projects. Conventional formwork may not be as environmentally friendly and energy-saving as aluminum formwork. For instance, the extensive use of wooden formwork will consume a large amount of timber resources, which is not conducive to the protection of the ecological environment and forests. Steel formwork may generate waste due to rusting and other issues.

4, Scope of application

Aluminum formwork is suitable for use in walls, horizontal floors, columns, beams, stairs, window sills, floating boards, etc., and has strong versatility and standardization.

Although conventional formwork also has a wide range of applications, it may not be as flexible and efficient as aluminum formwork in some aspects.

◆ How to complete aluminium formwork construction in 5 days?

With our advanced aluminium formwork system, the construction phase for 1 floor can be reduced to 5 days.

1st Day

Firstly, the surveying and layout phase involves precise measurement and marking of the construction site. This step ensures proper alignment of the building, taking into account factors such as slope, orientation, and building codes. Utilizing advanced surveying equipment and techniques, the construction team establishes reference points and lines to guide subsequent construction activities.

Next, the installation of wall reinforcing bars and water and electricity are carried out according to the approved structural design. This includes placing steel bars within the walls to enhance their tensile strength and overall stability. This step is crucial for ensuring that the concrete structure can withstand various loads and stresses. Additionally, plumbing and electrical conduits are embedded within the walls.

2nd Day

The aluminium wall formwork is a specialized formwork designed for constructing concrete walls. The workers should perform aluminium formwork construction correctly, ensuring alignment with the reference lines established earlier, and taking appropriate measures to ensure tight and seamless connections between the aluminium wall formwork. One worker can install 30m2 aluminium formwork in one day.

3rd Day

On the third day, the task is to install aluminium formwork beams and slabs. They are essential parts of the concrete structure and provide support and positioning for concrete pouring. The construction workers ensure a strong and tight connection between the aluminium formwork beam and theformwork for aluminium slabs and aluminium wall formwork. Once the aluminium formwork system for sale is installed, the concrete pouring process can begin. These components of aluminium formwork provide a stable platform and ideal conditions for concrete pouring and curing.

4nd Day

Installing reinforcing bars and water and electricity on the aluminium concrete formwork slabs is an important step prior to pouring concrete. The installation of reinforcing bars aims to enhance the load-bearing capacity and structural strength of the entire floor, ensuring it can withstand the expected loads and pressures during normal usage conditions.

Simultaneously, the layout of water and electrical pipelines needs to consider the practical usage requirements and functional needs. This involves ensuring secure and reliable connections and facilitating future usage and maintenance.

5rd Day

The fifth day is a crucial stage for pouring concrete, and the aluminium formwork system is used for a monolithic casting method. It is necessary to follow a sequential order for walls, beams, and decks during the pouring process. This procedure is pivotal in ensuring a strong and stable building structure.

you can click our blog page for more informations about aluminium formwork technology suc as dismantling of aluminium formwork.

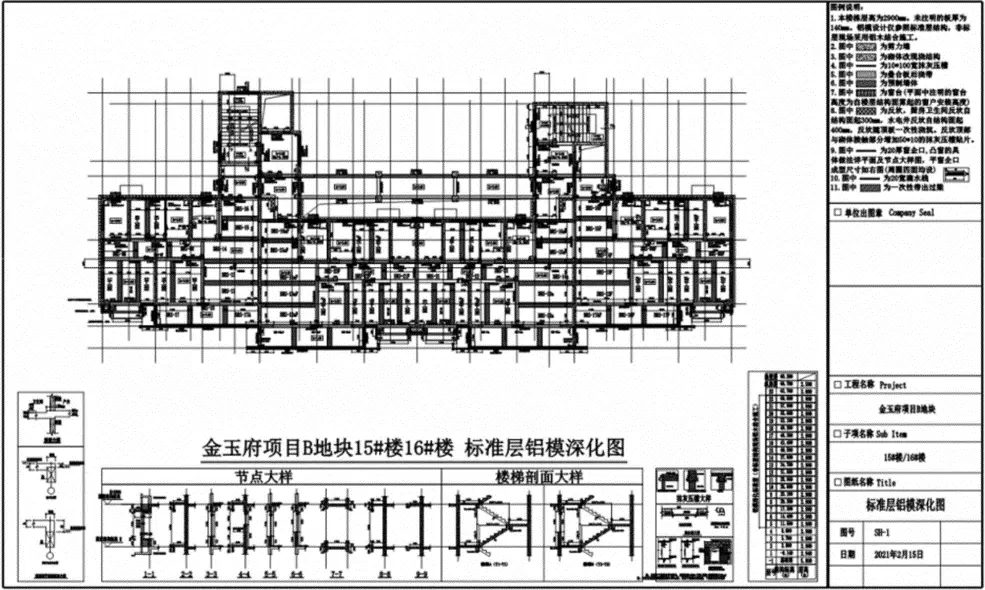

● Relationship between house drawing and aluminum formwork

The aluminium formwork advantages main include: the weight of aluminium formwork is light, strong bearing capacity, excellent structure forming effect, multiple aluminium formwork repetition use times, etc. The assembly of aluminium formwork system is simple and convenient, workers can do the concrete pouring in one time after the aluminium formwork installation finished, the construction is high speed and with good effect. Aluminium formwork has wide application range, the aluminium formwork technology can be used for the construction of all parts of building such as columns, walls, beams, slab floors, stairs, bay windows, balconies, etc. With aluminium formwork components, we can build various house type, no matter the commercial office or residential building, the quality aluminium formwork can completely meet your requirements. After the aluminium formwork set is removed, the surface of concrete is very clean and smooth, the inspection indicators such as the flatness, verticality, squareness internal and external angle, are normally exceeds the national standard, and can basically reach the requirement of clean concrete and rough decoration, users can directly putty and paint without plastering.

During the aluminium formwork construction, the construction drawings are very important. The aluminium formwork construction is a frame style construction, with high accuracy and small error. Due to it is hard to make aluminium formwork modification at the construction site, beside of the plane space layout diagram, the construction of aluminium formwork building also requires exactly structure construction drawings. With your structure drawing, we can do the aluminium formwork design and make the most economical aluminium formwork construction plan for you. To make full use the reuseable advantages of aluminium formwork, finally save construction cost and improve construction efficiency for you.

This is a plane space layout diagram (floor plan) for a residential with 150m² construction area, we can see it includes kitchen, dining room, living room, double balconies, 3 bedrooms, 3 washrooms, it is a comfortable and ideal house design. All parts of this house can be constructed with our aluminium formwork system, and will take about 300m² of aluminium formwork.

This is another house design for a residential which is also includes kitchen, dining room, living room, balcony, 3 bedrooms, 3 washrooms, with 110m² construction area. Although the construction area and internal layout are both different with previous design, but it also can be constructed with our aluminium formwork construction technology, and will take about 200m² of aluminium formwork.

When this two drawings are belong to the same floor of the building, if you don’t have special requirement on the construction period, you can do the construction of the two house one by one. In this condition, as one of professional aluminium formwork manufacturers, we will take full advantage of the aluminium formwork repetition use feature, to design a aluminum formwork solution that is as versatile as possible, make the most components of aluminium formwork set can be used in both house 1 and house 2. Combined with few non-standard aluminium formwork components, to finish the construction of this two house plans. In this way, you only need no more than 300m² of aluminium formwork, the aluminium formwork cost is lower. And even this two house plan are for different buildings, this aluminium formwork shuttering set is also fit for you.

If you want shorter construction period, we can make aluminium formwork design according to 500m², after finish the installation of aluminium formwork system frame, you can pouring the concrete of this two house plan in one time. And this 500m² aluminium formwork in construction can be repeated use into other floors and buildings construction, make full use of the repetition use advantage of aluminum formwork.

Based on this type of layout drawings, the designer will design the structure drawings accordingly, and then we will communicate the aluminium formwork details with your construction team, such as whether all the internal non-load-bearing walls constructed with components of aluminium formwork, the size and types of aluminium formwork, etc. then comprehensively consider of your requirements on construction period and budget cost of aluminium formwork, to do the aluminium formwork design calculation, and finally fix the solution of aluminium formwork system for sale.

We will use professional formwork matching software, to fix the aluminium formwork info such as specification, quantity, number and so on, and form the aluminium formwork checklist which includes all the aluminium formwork accessories. And arrange the production of aluminium formwork set (includes aluminium formwork panels, like aluminium wall formwork, aluminium formwork beams, aluminium formwork for slab, aluminium formwork staircase, etc.) and all the aluminium formwork parts (such as aluminium formwork props, aluminium formwork bracket, aluminium formwork wedge pin, aluminium formwork pin, aluminium formwork wedge, aluminium formwork clips, etc.), and provide the installation aluminium formwork drawing to you.