aluminium formwork installation

The importance and advantages of aluminium formwork installation are primarily reflected in three aspects: improving construction efficiency, ensuring construction quality, and controlling construction costs. Firstly, aluminium formwork exhibits the characteristics of rapid installation and construction speed, significantly reducing construction timeframes and enhancing construction efficiency. Secondly, aluminium formwork manufacturing process ensures high precision and reusability, guaranteeing construction quality. Once assembled, it forms a rigid structure that enhances the stability and load-bearing capacity of concrete structures. Lastly, aluminium formwork installation can save labour and materials, effectively controlling construction costs. Moreover, it provides better long-term economic benefits during extended usage.

● aluminium formwork construction technology

Before aluminium formwork construction, construction workers need to have a comprehensive understanding of aluminium formwork technology, including knowledge about aluminium formwork installation and removing, support systems, characteristics, and precautions. This will contribute to improving construction efficiency, ensuring construction quality, and maintaining the safety and sustainability of the construction process.

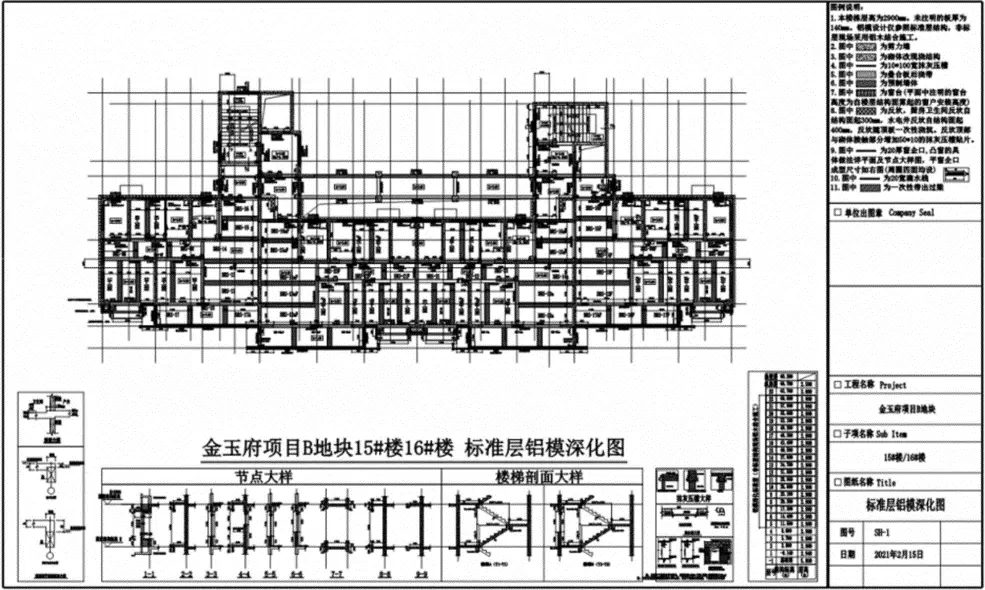

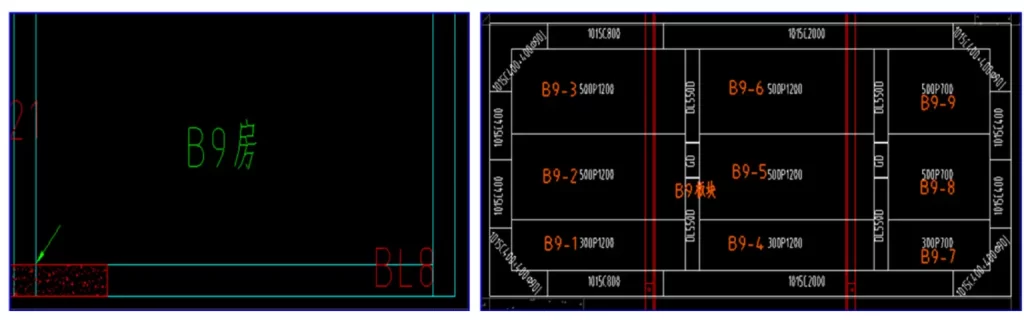

1.Based on the engineering drawings provided by the client, we are capable of designing and fabricating aluminium formwork components, including standard-sized aluminium formwork components, non-standard aluminium formwork components, and aluminium formwork accessories. The steel waler will be reinforced using steel profiles, while support will be provided by tool-type steel pipes with a diameter of φ48mm. The components of aluminium formwork will be fixed together using pins and wedges.

After the completion of the aluminium formwork design and manufacturing process, and upon inspection to ensure that it meets the engineering requirements, all aluminium formwork components need to be classified and marked with corresponding information. The aluminium formwork components are then packaged and transported to the construction site for organized stacking, with installation carried out according to the components of aluminium formwork numbers. The adjustable diagonal bracing is utilized to adjust the verticality of the entire components of aluminium formwork, while the adjustable shoring props are utilized to regulate the horizontal elevation, while the adjustable shoring props are utilized to regulate the horizontal elevation. The rigidity and overall stability of the components of aluminium formwork are guaranteed using the Flat Tie and Steel Walers. After the concrete strength reaches the specified demolding strength, the Props are retained while the aluminium wall formwork, aluminium formwork beams, and aluminium formwork floor slab are removed in sequence, and the cyclic construction of the next layer is quickly entered. During the installation and disassembly of aluminium formwork shuttering, it is necessary to strictly abide by the requirements of safety construction regulations.

2. construction process

measurement and marking —shear wall reinforcement binding ——aluminium wall formwork installation ——aluminium formwork beams installation ——aluminium formwork floor slab installation ——aluminium formwork installation acceptance—beam and slab reinforcement binding—reinforcement acceptance—pour concrete—components of aluminium formwork removal—transfer to next floor

● Aluminium formwork installation

1.aluminium wall formwork installation

(1.)The aluminium wall formwork is installed in the sequence of inner walls followed by outer walls, with adjustment of vertical and horizontal elevation after installation. After applying release agents to the aluminium wall formwork, starting from the inner corner formwork, the aluminium wall formwork is placed along the control line and temporarily secured with supports.

(2.) Prior to the installation of the outer aluminium wall formwork, Kickers must be installed and anchored to the concrete structure using fixed screws.

(3.) After the installation of aluminium wall formwork, flat ties are passed through the reserved holes on the formwork, and 5 steel walers are arranged to prevent twisting and misalignment of the aluminium wall formwork, ensuring a smooth structure.

2. diagonal bracing and soffit lengths installation

(1.) After the installation of aluminium wall formwork, diagonal bracing should be immediately installed for preliminary adjustment to ensure its horizontal elevation and verticality. For the verticality of wall columns, laser leveling instrument can be used for inspection and correction. The spacing between Diagonal Bracing should not be greater than 1500mm. For walls wider than 3000mm, at least two Diagonal Bracing must be installed, while walls narrower than 1200mm require at least one Diagonal Bracing. To control the deviation of wall column verticality to a maximum extent, it should be controlled within 5mm.

(2.)After the adjustment of aluminium wall formwork is completed, Soffit lengths should be installed to prepare for the next installation step.

3. aluminium formwork beams installation

(1.) After assembling aluminium formwork beams on the ground, they are securely fixed on the aluminium wall formwork by soffit lengths on both sides. During installation, it is advisable to install the bottom part of aluminium formwork beams first, followed by the install of the side part of aluminium formwork beams.

4. aluminium formwork components of floor slab installation

(1.)After the adjustment of all aluminium wall formwork is completed, the installation of Mid-beams begins. The two ends of the Mid-beams should be directly fixed on the Soffit lengths.

(2.)During the installation of aluminium formwork components of floor slab, we install them along the wall edge. We use pins to temporarily fix the panels, and finally tighten the pins uniformly. After the installation is completed, we use a level to measure the overall installation elevation and make adjustments to ensure that the flatness and elevation requirements are met before proceeding to the next construction step.

(3.)We use a tape measure to check whether the bottom of the beam meets the elevation and use a laser level or a level ruler to check whether the panel is horizontal. In case the requirements are not met, it is necessary to adjust each supporting rod to achieve the required level. To ensure the construction quality, the panel should be kept within a 5mm levelness tolerance.

● pouring concrete

After the aluminium formwork installation is completed, several aspects need to be checked before pouring concrete:

(1.)Ensure that the aluminium formwork components have been installed correctly according to the drawings, and that the deviation is within a controllable range;

(2.) All aluminium formwork components should be clean and coated with release agents;

(3.) The panel bottom and beam bottom shoring props should be vertical, and it should also be ensured that the shoring props are not loose;

(4.)Check whether the steel waler and diagonal bracing of the wall formwork and column formwork are installed correctly and firmly;

(5.)Check whether the flat tie, pins, and wedges are kept in place and secure.

(6.)Before pouring concrete, in order to ensure the even distribution of the load on the support system, the pouring should be started from the center and gradually spread outwards, so that the entire support system is centered.

● aluminium formwork components removal

(1.) Wall formwork removal: Generally, the wall formwork can be removed after 12 hours of concrete pouring. First, remove the diagonal bracing, then the Flat Tie, and finally the waller clamp, pins, and wedges. Use panel puller to pry the formwork off the wall. The removed aluminium formwork components should be cleaned in a timely manner and transported to the same position on the previous floor for storage.

(2.) Removing of aluminium formwork components for the floor slab: Generally, it is recommended to remove the aluminium formwork components for the floor slab after 36-48 hours. Remove the connecting pins between adjacent aluminium formwork beams and aluminium formwork components for the floor slab. Then, the formwork can be removed using a panel puller to remove it from the concrete. During the removal process, ensure that the shoring props remain in their original positions and do not loosen.

(3.)Shoring Props removal: Generally, the Shoring Props for the beam bottom and Deck Panel can be removed after 15 days, while the cantilever Shoring Props can be removed after 20 days. When removing each Shoring Prop, use a hammer to strike the adjustable fulcrum, then the Shoring Prop can be removed.

● Precautions for removing components of aluminium formwork:

1. Prior to removing, a working platform should be erected to ensure safety.

2. The concrete strength must reach the allowable value specified in the design before proceeding with the removing of components of aluminium formwork.

3. During the removing of components of aluminium formwork, it is crucial to avoid loosening or impacting the supporting rods.

4. After removing, it is necessary to promptly clean any dirt on the components of aluminium formwork and apply aluminium formwork cleaning chemicals.

5. Components of aluminium formwork that have undergone bending or deformation during the construction process should be repaired promptly.

6. Removed aluminium formwork accessories should be promptly cleaned, checked, and transferred to the upper level.

7. Removed components of aluminium formwork should be transported to the upper level through transfer holes, while scattered accessories should be carried using stairs.

● Recommended