Aluminium formwork panels

Price of aluminium formwork: 170USD/m2

The aluminium formwork panels are construction formworks made of aluminium alloy that serve as crucial components for supporting the weight and lateral pressure of concrete, ensuring concrete solidification and formation in accordance with design requirements.The aluminum formwork manufacturing process is advanced and can ensure the efficiency and accuracy of construction.

The aluminium formwork panels consists of four parts: formwork system, transition system, support system, and aluminium formwork accessories system, which are used to build walls, columns, and floors of buildings.After the concrete is poured and cured, the aluminium formwork components are removed from the structure, leaving behind a high-quality finished surface. This construction method is widely used in high-rise constructions, single-story villas, double-story villas, commercial and other large-scale construction projects. This aluminium formwork system is lightweight, durable, and easy to assemble, which makes the construction speed fast and cost-effective.

● Aluminium formwork panels parameters

| Item: | aluminium formwork construction |

| Material | 6061-T6/6082-T6 aluminium alloy |

| Thickness of Material: | 4mm |

| Type: | Flat formwork, corner formwork, beam formwork, etc. |

| Formwork Weight: | 18-22kg |

| aluminium formwork thickness: | 65mm |

| 6.Plastering cost | As the smooth effect after removing the formwork, there is no need to plaster. |

| Safe Working Load: | 60kN/m² |

| Cycle Times: | ≥200 |

| Shape: | Rectangular, customized |

| Size: | 0.5m-11.85m, non-standard: custom-made as your requirement |

| Process: | Drilling, bending, welding, precise cutting, punching, etc. |

| Package: | Standard pallet with waterproof film, or according to your requirement. |

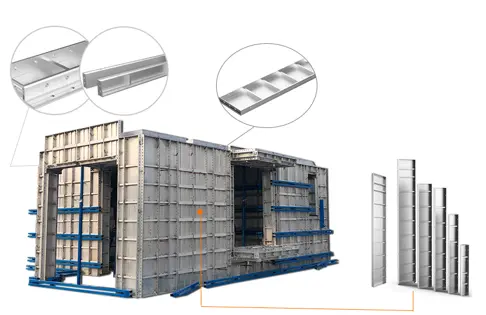

● Formwork for aluminium structure

★ formwork system

1. Aluminium wall formwork

The aluminium wall formwork is a standard formwork that constitutes the wall structure.

2. Aluminium formwork slab

The aluminium formwork slab is a standard formwork that constitutes the slab structure, providing a support surface for concrete pouring.

3. kicker in aluminium formwork

The kicker in aluminium formwork is a transfer slab formwork between upper and lower floors and plays a crucial role in the verticality and flatness of the upper and lower floors.

★ transition system

1. Rocker

Rocker is the supporting component for aluminium wall formwork .

2. Soffit length

Soffit length is a connecting component used at the intersection of aluminium formwork floor slab and aluminium wall formwork.

3. Mid-beam

Mid-beam is a connection component for interconnecting aluminium formwork floor slabs.

★ Aluminium formwork accessories system

1. Aluminium formwork flat tie

The aluminium formwork flat tie is used to secure aluminium wall formwork or steel waler, in order to prevent deformation during concrete pouring.

2. Steel Waler

Steel waler is used to reinforce aluminium wall formwork and aluminium formwork beams by connecting it with flat ties.

★ support system

1.Support for beams

The supporting for the aluminium formwork beams adopts adjustable shoring props, with a distance between columns not exceeding 1.2 meters, and is arranged on the bottom side of the beam according to the beam's length and load-bearing positions.

2. Support for slab

For formwork for aluminium floor slabs, adjustable shoring props are used for support, with the distance between supports not exceeding 1.3 meters. These props are arranged at the bottom of the formwork based on the length of the formwork for aluminium and the load-bearing positions. Additionally, a set of temporary supports is installed during concrete pouring.

3. Push pull prop

During the installation of push pull prop, one end is connected to the steel waler, and the other end is fixed to the ground, which is used to improve the stability and verticality of the aluminium wall formwork.

All support props are generally removed after 21 days.

● Aluminium formwork system for sale applications

The aluminium formwork system for sale is suitable for high-rise construction projects, such as buildings over 30 floors, row villas, and residential buildings with multiple similar layouts. It has a wider range of applications than traditional formwork. Traditional formwork is often time-consuming and material-intensive due to material or engineering factors, and it is difficult to achieve the desired effect. The aluminium formwork system for sale is suitable for wall, horizontal floor, column, beam, staircase, window sill, and floating slab construction. With just the planning drawings provided, the planning personnel can carry out detailed planning for the formwork, and organize production and construction accordingly.

The aluminium formwork system for sale is not suitable for projects with floor heights greater than 5 meters, frequent changes in layouts, or complex appearances. For example, in the basement structure, where more non-standard boards are required to be used in planning, it increases the cost and wastes building materials.

● FAQ

★aluminium formwork vs conventional formwork

The long-standing tradition of using wooden formworks has begun to be replaced by aluminium formwork construction. In the construction process, workers first assemble aluminium formwork panels to form an entire floor, and then pour concrete. The entire construction process is as easy and quick as building blocks, and the wooden boards and construction waste that are commonly seen on construction sites are nowhere to be found. The specific advantages of aluminium formwork construction are as follows:

1. Safety management: During ground construction, conventional wooden formworks require a variety of equipment and facilities such as unloading platforms and cranes for support, which can increase material costs, transportation costs, and safety risks for personnel. In contrast, formwork for aluminium only requires a small number of support rods and is designed with fixed holes for stability, making it convenient for vertical transport, on-site operations, personnel entry and exit, and material handling, and easier to manage.

2. Short construction period: An aluminium formwork system for sale can be used for a normal construction cycle of 4-5 days, while wooden formworks take more than 7 days, greatly accelerating the construction progress and reducing on-site management costs.

3. number of cycles: After calculation, an aluminium formwork system for sale only needs to be used 50 times or more to be cost-equivalent with traditional solid wood formworks. The number of aluminium formwork slab cycle more than 300 times.

4. concrete surface quality: When using aluminium formwork construction, the concrete surface quality is very smooth after the formwork is removed, completely meeting the requirements of the concrete single board and water, and there is no need to use putty for repairs, thus achieving cost savings.

5. Civilized construction: When using wooden formworks for construction, a large amount of construction waste is generated, including waste wood boards, sawdust, steel pipes, iron nails, etc. At the same time, it is necessary to spend time and energy on ground cleaning, resulting in material waste. In contrast, aluminium formwork construction almost does not produce any garbage on site, which is conducive to civilized construction management.

6. High recovery rate: Compared to traditional formworks, the recycling price of aluminium formworks is high, ranging from about 200-400 yuan per square meter, so the aluminium formwork cost is also lower.

7. Low-carbon environmental protection: Aluminium formwork material is one of the materials that meet the low-carbon emission requirements, and many developed countries do not allow the use of wooden formworks in engineering projects. Aluminium formwork is a sustainable and environmentally product.

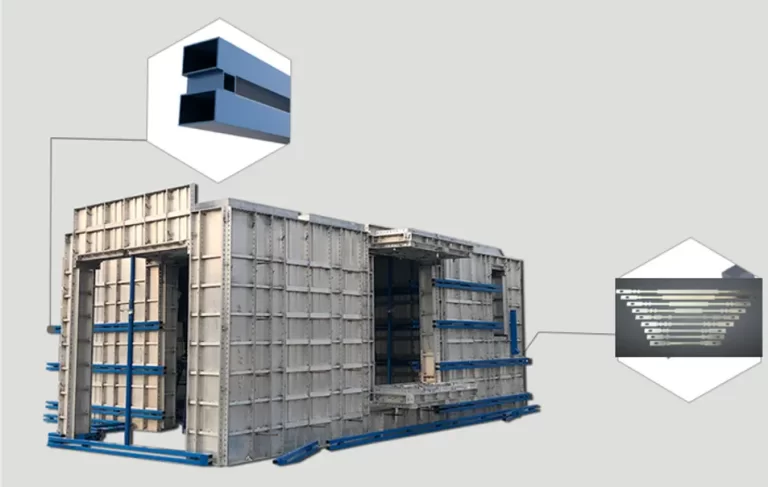

★ Aluminium formwork in india project

This case is the construction process of an ordinary house in India using aluminium formwork in construction. The external walls are constructed entirely from reinforced concrete, while partially reinforced concrete is used for the internal walls. Meanwhile, the roof utilizes a wooden structure. During aluminium formwork construction in this project, flat ties are used for reinforcement, with a thickness of 2 to 4 millimeters, and can withstand a pulling force of over 60kN. The thickness of the walls and columns is 100mm. The square steel walers are made from a single tube and measure 60 millimeters by 60 millimeters with a thickness of 2.5 millimeters. During the installation of the formwork, waller clamps are utilized to secure these square steel walers in place, thereby strengthening the overall structure of the aluminium formwork system for sale.

During the construction of aluminium formwork panels, thealuminium formwork flat tie are installed at the grooves of the ribs and fixed using pins to connect the two sides aluminium wall formwork, without the need for drilling holes in the formworks. Once all the aluminium formwork panels are removed, the extended parts of the flat ties can be cut off. Moreover, the breaking point is located 5 millimeters inside the wall and will not affect subsequent decoration processes. So, the construction of aluminium formwork cost india is low.

● Recommended