Aluminium formwork vs conventional formwork

● Aluminium formwork advantages

The aluminium formwork system is a construction formwork system manufactured using aluminium alloy material. It possesses the following characteristics:

1. Lightweight and high strength: Aluminium formwork is lighter than conventional wooden formwork while maintaining high strength. It offers convenience and flexibility during the construction process and can bear significant loads.

2. Excellent durability: Aluminium alloy material exhibits exceptional corrosion resistance, enabling it to withstand most physical and chemical damage. The aluminium formwork can be used for an extended period without being easily affected by environmental factors, resulting in a longer lifespan.

3. Easy and fast installation: With a modular design, aluminium formwork components have a simple structure and can be easily assembled and disassembled. Compared to conventional wooden formwork, it allows for quicker installation, saving both labour and time costs.

4. Smooth and aesthetically pleasing surface: The formwork's surface is meticulously treated, resulting in a smooth and flawless finish without noticeable gaps or flaws. This enables aluminium formwork construction to exhibit a good appearance, reducing the need for additional finishing work.

5. Reusability: Aluminium formwork profiles possess excellent reusability, allowing them to be used repeatedly in multiple construction projects. This reduces material waste and saves construction costs.

6. Environmentally friendly and sustainable: Aluminium formwork material is made of T6061 aluminium alloy, which has a high recycling rate and meets the requirements for environmental sustainability. It reduces the demand for wood and minimizes deforestation.

The aluminium formwork advantages are evident, with its lightweight and high strength, excellent durability, easy and fast installation, smooth and aesthetically pleasing surface, reusability, and environmental sustainability. It has been widely applied in construction, improving construction efficiency, reducing costs, and being environmentally friendly. With the continuous development of modern construction technology, the aluminium formwork system holds even broader prospects in the construction industry.

● Wooden formwork

conventional formwork refers to the commonly used wooden formwork system in construction. It has the following characteristics:

1. Commonly used materials: The main materials used in conventional formwork are wood, such as plywood and timber. These woods are widely available and have a lower cost.

2. Mature construction methods: The construction methods used in conventional formwork are relatively mature. Construction workers are familiar with the operation process and can quickly adapt. This has contributed to the widespread application of conventional formwork in construction.

3. Average strength and stability: The strength and stability of conventional formwork are lower compared to the aluminium formwork system. It cannot withstand heavy loads. Therefore, it is not suitable for projects that require high load-bearing capacity or resistance to wind pressure and seismic forces.

4. Longer installation and dismantling time: conventional formwork requires more time and manpower for installation and dismantling. This increases the construction timeline and costs.

5. Lower efficiency: conventional formwork often requires on-site customization and processing by carpenters, which demands higher technical skills and leads to lower construction efficiency.

6. Potential generation of more waste: The use of wood in conventional formwork may result in a significant amount of waste after construction completion, increasing the workload for cleanup and disposal. This can lead to resource waste and environmental pollution.

conventional formwork is widely used in construction due to its mature construction methods and lower material costs. However, aluminium formwork vs conventional formwork, conventional formwork has certain disadvantages in terms of strength, stability, installation speed, flexibility, and sustainability. When choosing formwork for construction projects, it is important to consider specific project requirements and weigh the advantages and disadvantages of each system to make a rational decision.

● Aluminium formwork vs conventional formwork

| aluminium formwork vs conventional formwork construction technology comparison | |||

|---|---|---|---|

| Num | Project | Aluminium formwork | Wooden formwork |

| 1 | concrete surface quality | the surface is smooth and even | the surface is coarse |

| 2 | concrete surface quality | the surface is smooth and even | the surface is coarse |

| 3 | construction accuracy | high precision of horizontal and vertical | Poor horizontal and vertical accuracy |

| 4 | Use of hoisting machinery | no | yes |

| 5 | scaffolding requirements | low | high |

| 6 | Leakage situation | No leakage, no need to clean up | There are many slurry leakages, requiring personnel to clean up |

| 7 | trash removal fee | low | high |

| 8 | Change project cost | high | low |

| 9 | Concrete pouring, steel bar process requirements | low | low |

| 10 | construction personnel requirements | Low technical requirements and minimal personnel needed | High technical requirements and a large number of personnel needed |

| aluminium formwork vs conventional formwork normal project comparison | |||

|---|---|---|---|

| Num | Project | Aluminium formwork | Wooden formwork |

| 1 | Material | 4mm thick aluminium formwork | 20mm plywood |

| 2 | weight(kg) | middle | middle |

| 3 | carrying capacity( KN/m2) | 60 | 30 |

| 4 | Construction period | 4-5days | More than 9 days |

| 5 | Formwork dismantling time | Formwork removal for columns and shear walls within 24 hours, and formwork removal for floor slabs within 36 hours | removal of columns and shear walls formwork after 168 hours |

| 6 | construction difficulty | easy | hard |

| 7 | Maintenance costs | low | high |

| 8 | construction efficiency | high | low |

| 9 | Application range | Walls, columns, beams, slabs, bridges | Walls, columns, beams, slabs, bridges |

| 10 | renovation time | Save plastering time | normal |

● Structure and Material Comparison

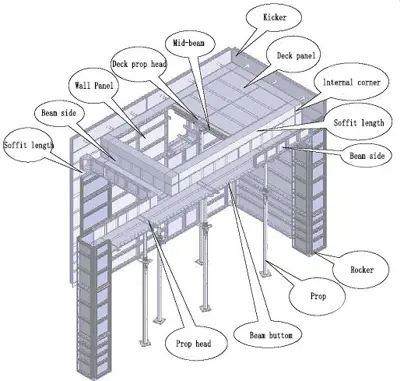

◆Structure and Materials of Aluminium Formwork System

1. Aluminium frame: The main structure of aluminium formwork panels is composed of an aluminium alloy frame, which has the characteristics of lightweight and high strength, allowing it to withstand significant construction loads.

2. Aluminium panels: The panels of aluminium formwork panels are made of aluminium alloy materials, boasting good corrosion resistance and surface flatness, ensuring a smooth and aesthetic appearance of the formwork surface.

3. Connectors: Assembly is achieved using aluminium formwork accessories, which are usually designed with special features to ensure stability and safety during the construction process.

◆Structure and Materials of Conventional Formwork

1 Wooden frame: The main frame of conventional formwork is typically constructed using wooden materials. These wooden frames can be customized in size and shape to support the loads during concrete pouring.

2. Surface covering: The wooden frame is covered with surface materials like plywood. These materials provide a smooth surface required during the construction phase and withstand the pressure during concrete pouring.

3. Connectors: Various connectors, such as bolts and nails, are used in conventional formwork to secure the wooden frame and surface covering, ensuring the stability and safety of the formwork.

● Construction Efficiency Comparison

◆ Efficiency of aluminium formwork construction:

1. Quick assembly and disassembly: Aluminium formwork panels are designed with a modular approach and simple connectors, allowing for fast assembly and disassembly. The construction cycle for one floor takes around 4 days, saving construction time.

2. Reduced construction cycle: Aluminium formwork construction technology is advanced. Aluminium wall formwork can be removed within 12 hours, the slab formwork within 24 hours, and aluminium formwork beams within 36 hours. This enables quick completion of construction tasks, reducing the overall construction cycle.

3. Improved worker productivity: Aluminium formwork panels are user-friendly and lightweight, reducing the labor intensity for workers during formwork erection, adjustment, and dismantling. A single worker can install 30 square meters per day, enhancing work efficiency.

◆ Efficiency of Conventional Formwork:

1. Longer installing and dismantling time: Conventional formwork installation is complex, and a worker can only install 10 square meters per day. Construction personnel needs to spend more time on assembly and dismantling.

2. Longer construction cycle: Due to the longer time required for installing and dismantling conventional formwork, the construction time for one floor is around 9 days. Additionally, the formwork needs to remain in place for at least 48 hours before removal, resulting in a relatively extended overall construction cycle.

3. Lower efficiency: Conventional formwork requires skilled carpenters for on-site customization and fabrication, with higher technical requirements. As a result, the flexibility in design and construction efficiency is relatively lower.

So, the aluminium formwork construction process exhibits higher construction efficiency by enabling quick assembly and dismantling, reducing the construction cycle, and improving worker productivity. In contrast, conventional formwork requires a longer time for assembly and dismantling, resulting in a relatively extended construction cycle and lower flexibility and efficiency. Therefore, in situations that call for efficient construction, aluminium formwork panels are the ideal choice.

● Quality and Safety Comparison

◆ Quality and Safety of the aluminium formwork system

1. Strength and Stability: The aluminium formwork system is manufactured using aluminium alloy materials, providing high strength and stability. It can withstand a load of 60KN/m2, ensuring safety during the construction process.

2. Wind Pressure Resistance and Seismic Capability: The aluminium formwork system possesses excellent resistance to wind pressure and seismic capability, enabling it to remain stable under harsh weather conditions and offer a certain level of protection during earthquakes.

3. Safe Usage: The aluminium formwork design is rational and user-friendly, reducing the possibility of human operational errors. Moreover, the stable structure effectively prevents formwork detachment or collapse, improving construction safety.

Users can review "Aluminum Formwork Advantages And Disadvantages" for more information.

◆ Quality and Safety of conventional Formwork

1. Limited Strength and Stability: conventional formwork often utilizes wooden materials, which have relatively low strength and stability. It can withstand a load of 30KN/m2. There may be risks of deformation and damage when facing larger loads.

2. Insufficient Resistance to External Forces: conventional formwork exhibits weak resistance to external forces such as wind pressure and earthquakes, making it prone to damage or deformation, thus affecting construction safety.

3. Higher Safety Risks: The assembly and dismantling processes of conventional formwork are complex and require high skills from workers, thereby posing safety risks. Additionally, issues such as moisture absorption, corrosion, and deformation in wooden materials may lead to unstable formwork structures, increasing the risk of construction accidents.

To sum up, the aluminium formwork system demonstrates higher quality and safety performance, encompassing strength, stability, wind pressure resistance, seismic capability, and providing a secure usage environment to minimize the risk of accidents. In contrast, conventional formwork is limited in terms of quality and safety performance, with lower strength and stability, insufficient resistance to external forces, and higher safety risks. Therefore, in terms of quality and safety performance, the aluminium formwork system is a more reliable and secure choice.

● Economy and sustainability Comparison

◆ Economics and sustainability of aluminum formwork system

1. Reduced labor and material costs: The aluminium formwork system is lightweight, easy to install and dismantle, and does not rely on large equipment, thereby reducing labor costs and equipment rental expenses. Although the initial investment might be higher, it possesses excellent reusability, allowing for up to 300 cycles of usage. After around 60 cycles, the aluminium formwork panels cost becomes significantly lower than that of conventional wooden formwork.

2. Reuse and waste reduction: Components of aluminium formwork can be recycled and reused, minimizing waste generation and reducing environmental impact. Effective management and maintenance extend its lifespan, minimizing waste to the greatest extent possible.

3. Energy and resource efficiency: The aluminium formwork manufacturing process is relatively simple, resulting in energy and resource savings. Compared to conventional formwork, aluminium formwork material requires fewer resources, reducing the demand for wood.

◆Economics and sustainability of conventional formwork

1. Increased labor and material costs: conventional formwork requires more labor during the construction and dismantling processes, resulting in higher labor costs. Additionally, conventional formwork needs an amount of wood, increasing material costs.

2. Generation of substantial waste and inefficiency: conventional formwork generates a large amount of waste during usage and is not easily recyclable, placing a burden on the environment. Furthermore, due to the relatively unstable structure of conventional formwork, frequent replacements, and repairs are necessary, leading to increased waste.

3. Waste of resources: The manufacturing process for conventional formwork is comparatively complex and consumes a substantial amount of resources. Moreover, since conventional formwork is not easily reusable, new formwork needs to be purchased for each construction project, resulting in energy and resource waste.

In summary, the aluminium formwork system offers higher economic and sustainability advantages by reducing labor and material costs, promoting reuse and waste reduction, and conserving energy and resources. In contrast, conventional formwork exhibits certain disadvantages in terms of economics and sustainability, requiring more labor and material costs, generating significant waste and inefficiency, and wasting energy and resources. Therefore, in terms of both economics and sustainability, the aluminium formwork system is a preferable choice.

The aluminium formwork system offers significant advantages and suitability over conventional formwork, excelling in terms of economics and sustainability. It can reduce labor and material costs, promote reuse and waste reduction, and conserve energy and resources. These attributes make the aluminium formwork system an ideal choice in the field of construction.

On the other hand, conventional formwork exhibits certain disadvantages in these aspects, requiring more labor and material costs, generating substantial waste and inefficiency, and wasting energy and resources. However, conventional formwork still holds value in specific applications such as buildings with special shapes or lower requirements.

Users can also contact us via WhatsApp to analyze and discuss specific project requirements for selecting the appropriate formwork solution.

● Recommended