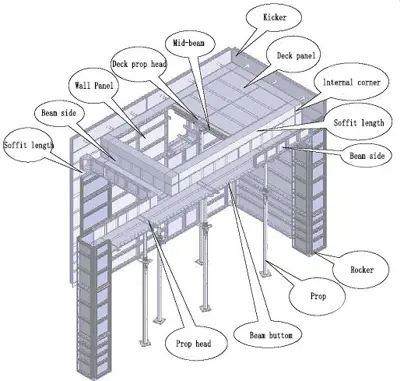

aluminium formwork components

Aluminium formwork components enable the rapid assembly of the overall framework of a building and provide support for concrete pouring, thereby enhancing construction efficiency and quality. These aluminium formwork components are easy to assemble, and each aluminium formwork component can be secured through the coordination of aluminium formwork accessories. Furthermore, the aluminium formwork system features the advantages of being detachable and reusable, which saves construction costs and time.

● aluminium formwork components

1.Aluminium wall formwork

Aluminium wall formwork provides support for the pouring of concrete walls.

2.Rocker

Rocker is the supporting component for aluminium wall formwork.

3.Kicker

The kicker in aluminium formwork is the transition formwork for the upper and lower floors. It plays a vital role in maintaining the verticality and flatness of the upper and lower floors of the building. The installation height of the kicker should be 50mm higher than the finished concrete surface.

4.External corner

Connects vertical or horizontal formwork at right angle.

5.lnternal corner

lt connects two pieces of vertical formwork pieces at their exterior.

External Corner: lt forms the external corner of the formwork system.

Soffit Corner: lt forms the vertical internal corner between the walls and the beams, slabs, and the horizontal cornice between the walls and the beam slabs and the beam soffit.

6.Beam side

It forms the side of the beams.

7. Beam bottom

It forms the bottom of the beams, with 65mm wide flanges on both sides.

8. aluminium formwork props head

The aluminium formwork props head is connected to the adjustable shoring props to provide support for the bottom formwork of the beam.

9. slab formwork

The deck panel provides a level support surface for concrete pouring.

10. Mid-beam

The mid-beam is used to connect the components between the slab formwork blocks.

11. Soffit length

Soffit length is used for the transition between wall panel and slab formwork at the intersection.

12. Deck aluminium formwork props head

It is used to provide support for the floor, allowing the transfer of loads through the use of an adjustable prop.

● aluminium formwork accessories

1.Stub pin

The function of aluminium formwork accessories, wedges is to connect and secure aluminium formwork components. Aluminium formwork pin HS code: 76161000.

2. Formwork Releasing agents

Formwork Releasing agents is a coating applied to the surface of aluminium formwork components before pouring concrete. Its purpose is to minimize adhesion between the concrete and the surface of aluminium formwork components, making the removal process easier.

3.aluminium formwork flat tie

In the construction of concrete walls, aluminium formwork flat tie is utilized to connect the inner and outer aluminium formwork components of the wall, serving to secure the aluminium formwork components and control the thickness of the wall. This is a crucial step that directly impacts the quality and shape of the wall.

4.aluminium formwork props

Aluminium formwork props, including shoring props and push-pull props, serve as supports in concrete structures to ensure the stability of floors, beams, and cantilever structures. Shoring props are used to adjust height, while push-pull props are employed to adjust verticality, with an error range controllable within 3-5mm.

● Aluminium wall formwork

◆aluminium wall formwork installation technology:.

1、Aluminium wall formwork consists of inner aluminium wall formwork, outer aluminium wall formwork, rockers, kickers, steel walers, tie rods, and push-pull props.

2、 The bottom Rocker and wall formwork are connected by tie rods, and the wall formwork and the Kicker are connected using dowel pins, with a spacing of 300mm between dowel pins.

3、The steel waler is set to be 4 on the inner side and 5 on the outer side. The distance of the first steel wale from the ground is 250mm, and the spacing between each steel wale is less than or equal to 700mm.

4、 The horizontal spacing of aluminium formwork flat ties should not exceed 800mm.

◆aluminium wall formwork Installation Precautions

1. Assembly should be carried out according to the aluminium wall formwork assembly drawing and in combination with the numbering.

2. When assembling the aluminium wall formwork, it is recommended to start from the end because each panel may have slight negative deviations in dimensions. Therefore, it is not necessary to install all the pins and wedges; installing only 50% of the pins and wedges is sufficient. We suggest two-person cooperation during the assembly process to ensure the correct installation of the aluminium wall formwork.

3. Start by completing the assembly of one side of the aluminium wall formwork, and install the aluminium formwork flat ties for fixation. Next, proceed with the assembly of the other side of the aluminium wall formwork, ensuring that all pins and wedges are tightened.

4. aluminium wall formwork Before using the pins, check whether the position of the pulling tab pressure groove, plastering pressure groove, water voltage groove, water and electricity hole, and the hole of the pulling screw is correct. After the inspection is correct, the pins can be fastened.

● Aluminium formwork beams

◆aluminium formwork beams installation technology

1. Aluminium formwork beams consist of bottom formwork, rocker, side formwork, and beam supports. Support rods are installed under the beam supports, with a spacing of ≤1200mm between the support rods.

2. Aluminium formwork accessories are used for fixed connections between the bottom formwork, rocker, and side formwork.

3. aluminium formwork accessories arrangement: Dowel pins should be installed at both ends of the formwork, and the spacing between dowel pins in the middle should not exceed 300mm.

4. Aluminium formwork beams are connected to the aluminium wall formwork via the soffit length.

◆aluminium formwork beams Installation Precautions

beam bottom formwork

1. After adjusting the aluminium wall formwork, begin installing the beam bottom formwork, starting from one end of the beam and moving towards the other end sequentially.

2. Assemble the beam bottom formwork on the ground, connect it to the wall formwork using dowel pins, and install the support vertical rods.

3. The aluminium formwork accessories should be securely fastened in place during installation.

4. During the installation process, check whether the position of the pulling tab pressure groove, plastering pressure groove, water voltage groove, water and electricity hole, and the hole of the pulling screw is correct. If any inconsistencies are found with the design, adjustments should be made promptly.

beam side formwork

1. The beam side formwork is connected to the beam bottom formwork using rocker and secured with aluminium formwork accessories . Installation is carried out sequentially from one end of the beam to the other.

2. After the installation of the beam side formwork, install the Soffit length of the board bottom.

3. After installation, it is necessary to check the elevation and positioning of the aluminium formwork beams.

● slab aluminium formwork components

◆ slab aluminium formwork components installation technology

1. The middle beam, supports, and slab aluminium formwork components are fixedly connected using dowel pins.

2. The principles of dowel pin arrangement are as follows: slab aluminium formwork components should be installed at both ends of the formwork, and the spacing between dowel pins in the middle should not exceed 300mm.

3. Aluminium formwork accessories are used to connect the aluminium formwork components of the slab.

◆ slab aluminium formwork components Installation Precautions

1. Prior to the installation of the slab aluminium formwork components,it is necessary to inspect the beam spacing and ensure that the dimensional deviation is ≤3mm. If not, please adjust the beam spacing.

2. During the assembly process, it is important to check the correct positioning of the reserved openings, including alignment holes, material transfer ports, and pre-embedded openings for utilities.

3. When installing the middle beam, it is essential to ensure that the support positions align with the design and that the supports are erected synchronously with the middle beam.

4. After the installation of the slab aluminium formwork components,diagonal bracing should be added according to the layout diagram.

◆ Calibration and inspection of slab aluminium formwork components

1. During the installation process, attention should be paid to controlling the elevation of the slab aluminium formwork components and the levelness of the floor.

2. After installation, each slab aluminium formwork components must undergo a check and calibration of elevation and levelness.

3. The vertical deviation of the support columns for the floor and beam bottoms should not exceed 50mm.

4. The maximum allowable horizontal deviation for the top slab aluminium formwork components is ≤5mm.

If you want to know the detailed process of aluminium formwork components from installation to dismantling, you can check this article "Aluminium Formwork Installation And Dismantling".

● Recommended