Advantages of aluminium formwork material

Aluminium alloy is one of the most widely used non-ferrous metal materials in the industry, extensively applied in fields such as aviation, aerospace, automobile, machinery manufacturing, shipping, and chemical industry. Compared to other structural materials, aluminium alloy has low density but high strength. Additionally, aluminium alloy has good plasticity and can be processed into various profiles with different shapes. Because of its excellent electrical conductivity, thermal conductivity, and corrosion resistance, aluminium alloy also has broad industrial applications.

Aluminium formwork material is aluminium alloy(6061-T6), that also inherits these advantages. It has lightweight, has high strength, excellent plasticity and processing performance, and can be processed into structures of various sizes according to the construction needs. Furthermore, aluminium formwork system also features good electrical conductivity, thermal conductivity, and corrosion resistance, enabling it to be used for extended periods of time without being easily corroded or damaged. aluminium formwork system is extensively applied in modern construction and has a positive role in improving construction efficiency and reducing labor and material costs.

● aluminium formwork profile

| Aluminum alloy model | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | other | Al | |

| single | total | minimum | |||||||||

| 2024 | 23.2 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | margin |

| 5052 | 25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | -- | 0.05 | 0.15 | margin |

| 5083 | 23.8 | 0.4 | 0.1 | 0.3-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | margin |

| 6061 | 23.6 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | margin |

| 7050 | 23.5 | 0.15 | 2.0-2.6 | 0.1 | 1.9-2.6 | 0.04 | 5.7-6.7 | 0.06 | 0.05 | 0.15 | margin |

| 7075 | 23.6 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | margin |

The 2xxx series represents 2024 aluminium alloy, which is characterized by high hardness and copper content of about 3-5%. Although it belongs to the aviation-grade material and has a wide range of applications in aviation and aerospace fields, it is not commonly used in conventional industries.

The 5xxx series represents 5052 and 5083 aluminium alloys, which are mainly composed of magnesium with a magnesium content between 3-5%, also known as aluminium-magnesium alloys. This type of alloy has the characteristics of low density, high tensile strength, high elongation, and good fatigue strength, making it a high-strength and corrosion-resistant aluminium alloy. At the same time, the 5xxx series aluminium alloy is widely used in conventional industries such as automobiles, ships, and construction.

The 6xxx series represents 6061 aluminium alloy, which mainly contains magnesium and silicon elements. It is a cold-treated aluminium forging product suitable for applications with high requirements for corrosion resistance and oxidation resistance. It has the advantages of good machinability, easy coating, and processing, so it is often used in the production of aluminium formwork components.

The 7xxx series represents 7075 aluminium alloy, which mainly contains zinc and belongs to the aluminium-magnesium-zinc-copper alloy, an aviation-grade super-hard aluminium alloy. This alloy has good wear resistance and weldability but poor corrosion resistance. Therefore, it is widely used in aerospace and other fields.

The raw material of aluminium formwork manufacturing process is 6061 aluminium alloy or 5052 aluminium alloy.Both of these materials exhibit high strength, wear resistance, and are easy to shear and process into various sizes of sheets, facilitating aluminium formwork installation.

● Aluminium alloy characteristics

1.Lightweight and high strength: Aluminium alloy is lighter in weight compared to other common metallic materials such as steel, yet it possesses high strength. This makes aluminium alloy an ideal structural material that can reduce the self-weight of structures and enhance overall performance.

2. Excellent processability: Aluminium alloy exhibits excellent plasticity and forge ability, allowing for the production of various complex-shaped aluminium formwork accessories through various processing methods such as casting, extrusion, rolling, and stretching.

3. Corrosion resistance: Aluminium alloy forms a dense oxide film in the atmosphere, exhibiting excellent corrosion resistance. Additionally, aluminium alloy can further enhance its corrosion resistance through surface treatments such as anodizing, electrophoretic coating, etc.

4.Recyclability: Aluminium alloy is a recyclable material, offering the advantages of a circular economy. Not only does it reduce resource consumption, but it also helps minimize environmental pollution.

5.Flame retardancy: Aluminium alloy possesses good flame retardant properties, providing a certain level of protection against fire hazards.

● How to distinguish the quality of aluminium formwork panels

The primary raw material used in aluminium formwork panels is aluminium alloy. To produce high-quality products, it is necessary to select premium aluminium alloy materials. Here are several simple methods for assessing the quality of formwork panels:

一、look and touch

By observing and touching the surface lettering, inner and outer layers of aluminium formwork material, we can distinguish its quality.

1. High-quality aluminium formwork material usually adopts imported spray coding printing with clear writing. The labeling contents including trademark, manufacturer, address, telephone number, etc. are relatively true and clear. In contrast, inferior aluminium formwork material is generally printed with a common printer, with blurred writing and incomplete or absent labeling content.

2. High-quality aluminium formwork panels have high precision, with smooth and comfortable surface texture for both the outer and inner layers, and are flat and without impurities. On the other hand, inferior aluminium formwork panels have relatively poor quality due to cutting corners.

3. The wall thickness of high-quality aluminium formwork profile is uniform, the materials are closely combined, and the thickness and quality of the aluminium meet the relevant national standards. In contrast, the wall thickness of inferior aluminium formwork profile varies greatly, the aluminium sheet is thinner, and the gap is larger.

二、Burning

High-quality aluminium formwork welding uses ultrasonic lap welding or hydrogen arc welding method, and its interface is quite tight. After being ignited by a fire, the aluminium sheet will not fall off. In contrast, inferior aluminium formwork welding has loosely connected interfaces, and the aluminium sheet will fall off after burning.

三、 cut

High-quality aluminium formwork panels have a 5-layer composite structure, and the aluminium layer is tightly attached to the PE layer and is not easy to detach. In contrast, the aluminium layer of inferior aluminium formwork panels is not firmly bonded to the PE layer, and it is easy to peel off.

四、 test

The compressive strength of high-quality aluminium formwork panels should meet the standard, usually above 100MPa, the interlayer shear strength should reach 40-50MPa, and the bending strength index is usually 110-130MPa. However, for inferior aluminium formwork panels, due to its poor material performance, pressure resistance performance is low, making it difficult to meet usage requirements.

● aluminium formwork advantages

1.Lightweight: While aluminium alloy materials have high strength and rigidity, aluminium formwork weight is relatively light, making aluminium formwork shuttering more lightweight than wooden formwork, making it easier to operate and move during construction.

2.Overall stability: aluminium alloy materials have good surface flatness and dimensional stability, so aluminium formwork construction can ensure the flatness and levelness of the construction surface, thereby improving the overall quality of the building.

3.Strong Durability: Due to the corrosion resistance, wear resistance, and oxidation resistance characteristics of aluminium alloy, aluminium formwork panels can maintain stability and durability during long-term use.

4.High safety: aluminium alloy has good load-bearing and wind-resistance capabilities, so aluminium formwork construction ensures the safety and stability of the building during use.

● aluminium formwork construction scenario

1. Large-span roofs and bridge structures

Aluminium formwork China possesses advantages such as lightweight, robustness, durability, and resistance to deformation. It can effectively reduce the self-weight of structures, enhance overall seismic and wind resistance capabilities, meet the demands of large-span designs and long-term usage, while simultaneously improving the stability and reliability of engineering projects.

2. Damp, acidic, or alkaline environments

Aluminium alloy itself possesses high corrosion resistance. It can be utilized in damp, acidic, or alkaline environments without being susceptible to corrosion and oxidation. This enables aluminium formwork China to be widely applied in construction projects in harsh conditions such as marine climates and acid rain. Moreover, the surface of aluminium formwork China is typically subjected to special treatments such as anodization or the application of anti-corrosion coatings. These treatments enhance its corrosion resistance and improve its ability to withstand chemical substances. Additionally, the surface is smooth and robust, making it less prone to the accumulation of dust and dirt, facilitating easy cleaning and maintenance. This makes it an ideal choice for engineering projects in adverse weather conditions that require resistance to chemical substance erosion.

3.Demountable structure

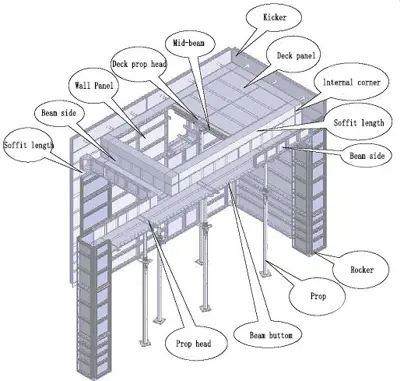

Aluminium formwork design allows for quick assembly and disassembly through the use of connectors and supporting systems. It typically adopts a modular design, where modules are connected using aluminium formwork parts, allowing for flexible connections and detachments, making it convenient to adjust the structural form and dimensions. Additionally, aluminium formwork slab cycle adoption offers good reusability and environmental friendliness. After a project is completed, it can be disassembled and reused in other projects, reducing material waste.

● Recommended